|

Food processing applications - challenges to

look out for

When specifying drives and

controls for food processing and manufacturing sites, there are some

common, and some more unusual, challenges.

Find out below how we

created a solution for a door that hadn’t operated properly since the day

it was installed. And see the examples to help you start thinking about

requirements when talking to your customers.

Maintaining door

functionality

Often, food processing sites will have multiple internal doors to

separate different areas of the site. For example, warehousing or storage

from food production. These will run numerous operations each day so

durability of the doors and drives is key.

Minimising heat loss and gain

High speed opening and closing is essential for temperature control.

In a food processing plant, maintaining temperatures in certain areas,

such as cold storage, is crucial. Doors need to be open for a minimum

amount of time to prevent heat gain or loss

Meeting challenging hygiene

standards

In a

plant that processes a variety of foods at the same time, it has to

prevent cross-contamination and maintain a high standard of hygiene to

ensure products are safe for consumers.

In many of the cases

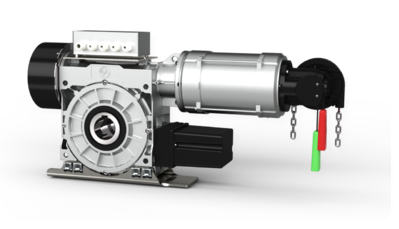

above, our customers specify fabric speed doors for which our Safedrive® Fi is ideal. It was specifically developed

for speed, frequency of use and durability. Exceedingly difficult conditions

Our technical team were recently

tasked to create a solution for a fabric speed door on an industrial steam

washer room in a cream cake factory. This was to replace an existing door

that hadn’t worked properly since it was installed.

Our customer explains: “The washer uses steam to clean trays used in the

cake manufacturing process. The steam quickly condenses on to the walls

and every item within the room, including the door. When the cleaning

process has finished, the floor is hosed down to ensure no deposits of

cream leave the room. The condensation produced rendered the existing door

useless.”

GfA’s Robert Booth says: “The door drives and controls needed to be

capable of fast operation of the door to stop warm vapours escaping into

colder rooms where the cakes are produced and stored, but we quickly

established that the environment was not suitable for the Safedrive® Fi or

conventional high-speed door drives. We needed to look at a solution that

was both water and vapour resistant, above the traditional IP65-rated

protection.”

In answer to similar challenges, GfA has developed IP65i; an enhanced IP65

model rangefor mechanical limit drives. Unlike normal IP65 protection,

IP65i prevents damage caused by the ingress of water vapour, which

condenses out on to the electrical components. IP65 only stops the ingress

of liquid water.

On traditional drive units, the limits are on a circuit board within

a sealed box. The box prevents liquid water getting to the circuit board,

but in high humidity it cannot stop water vapour. Once inside the box the

vapour condenses back to water, soaking the circuit board and causing

electrical damage.

In IP65i drives, all the limit switches are totally encapsulated.

Although vapour can still enter the box, any condensate cannot get to

individual switches or cause them to short circuit with a neighbouring

switch.

The IP65i drive units also have a special corrosion resistant finish

applied to the motor and the gearbox. This is also applied to the

hollowshaft.

Robert continues: “We designed a solution that

incorporated an IP65i-rated high-speed door drive unit sized to the door

in question with an electric motor designed to work off an inverter

control to ensure soft-start and durability. The proprietary inverter

control unit was installed in a special IP65 rated enclosure incorporating

an anti-condensation heater to keep the controls

dry.”

The customer reports that all is now working

fine! |